Considered the first newly constructed textile processing facility in North Carolina in the last twenty-five years, Echoview Fiber Mill is envisioned as a crossroads for industry and community.

The facility is intended to bring together fiber suppliers and users under one roof and to educate the broader community about the process. Towards this end, the building is a unique combination of an industrial facility and educational community center; implementing processing facilities adjacent to a community library, conference rooms, and a catering facility to serve both interior and exterior events.

The design of the building illustrates the process of turning fleece into fiber. The three core- ten steel roof forms, each with a subtly different pattern, represent the three distinct staples of the alpaca coat, each with a distinct fiber length or texture. The cypress represents the more vulnerable body of the animal with the fleece removed. As they patina, the core-ten and cypress cladding will merge with the vernacular barns and outbuildings of the western North Carolina landscape.

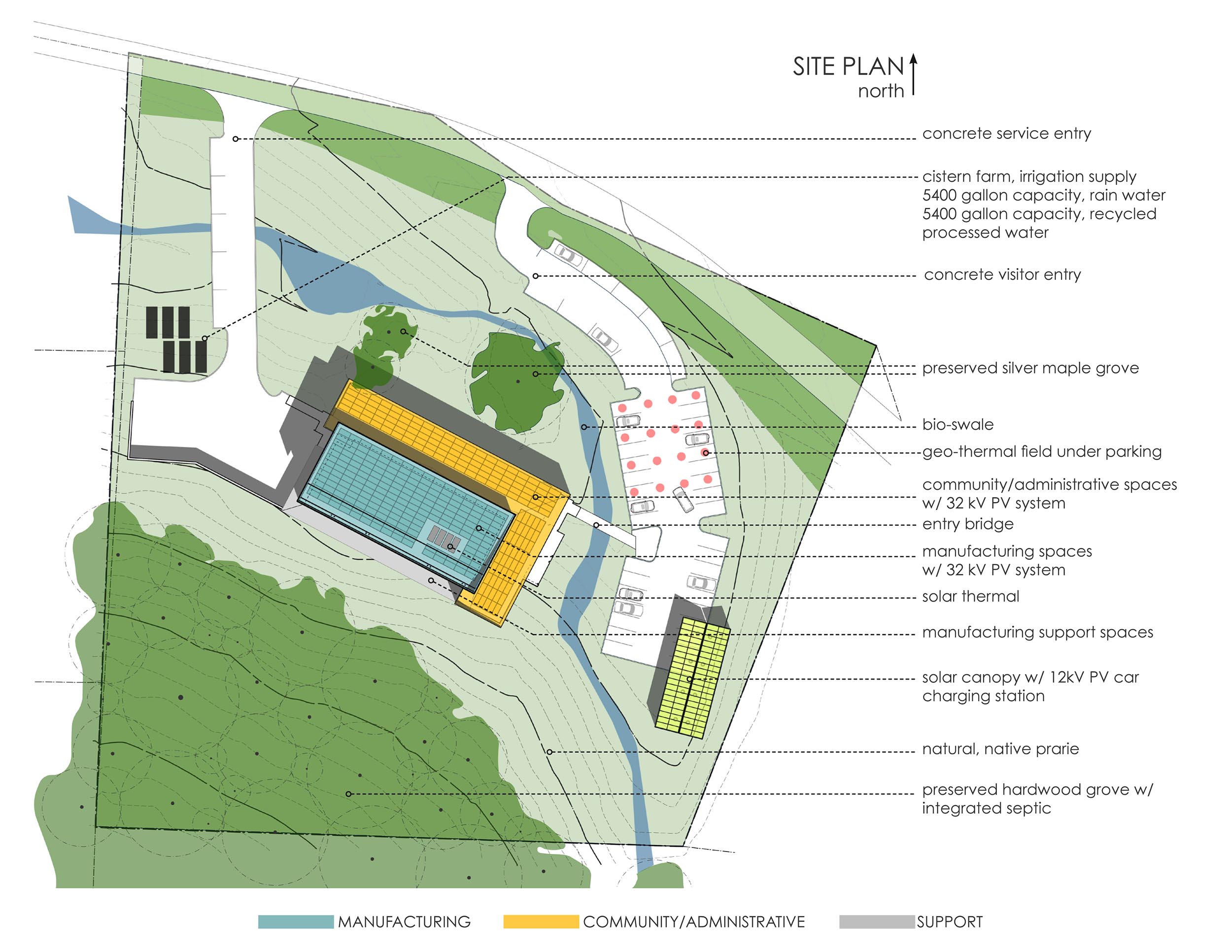

The owner’s commitment to a natural and sustainable fiber process enhanced with geothermal heat pumps, 90% natural daylighting, LED fixtures, a comprehensive building energy management system, low-flow fixtures, process water filtering, and rainwater harvesting help to reduce energy and water use by 40% over comparable buildings. A 76kw solar PV system provides electricity. All storm water is treated by on-site bioswales.

ECHOVIEW FIBER MILL

WEAVERVILLE, NORTH CAROLINA

Completed | 2012

Photographs | Northrup Pearce